Are your business processes creating value or waste?

Our recent article discussed when to consider engaging a business analyst and what we can learn from the business analysis. As a reminder - business analysis is a detailed study of a business process to determine what is happening in your current processes, what to improve and how to make the necessary improvements. This time we introduce the stages of the business analysis, discuss the value creation and waste in business processes and how to evaluate them.

What are the stages of a business analysis project?

A business analysis project can consist of six stages. The number of steps depends on the project goal, budget and schedule.

1. Identifying process architecture

In the first step, we create a sub-view of the business architecture - we map what the organization does. Business processes are typically divided into management, core and support processes. Then we compare these processes against the business strategy, identify the priority processes and decide which ones need more attention.

As a result of the first stage, a view of the business architecture is created. This stage is usually completed once, and all subsequent steps act as iterative cycles to ensure continuous process improvement.

2. Mapping of current business processes

We map the current (as-is) business processes in the second stage. Business process mapping in as-is has five steps:

- first, we establish the criteria of the process: what does the business process mean, what are the characteristics of the process, where does it start and end, and what is the input and output.

- next, we map activities and events between input and output as necessary and with reasonable detail based on the project's purpose.

- then we map the resources: who initiates the processes, who are the doers and participants in the events. Resources can be human and technological assets, both internal and external resources of the organization. If we know the activities and the participants, we can observe what information flows in the activities and to what extent the information is processed.

- next, we map the process conditions. Conditions can be activity dependencies, sequences, parallelisms, decision points, events, additional resources, etc. We already have a fairly detailed process model if the conditions are known.

- the last step is to define additional information based on the project's purpose.

As a result of the second stage, we have identified the priority business processes, and there is an understanding of the current situation.

3. Setting metrics and assessing value creation and waste

In the third step, we evaluate the value creation and waste in the processes. What is value and waste, and how to identify and assess them - we will write about this in more detail below.

„As a result of the assessment, we will have several ideas for improving processes. These ideas must be prioritized. We then identify the important business process changes that will bring the greatest positive impact," says Trinidad Wiseman business analyst Mihkel Lauk.

The evaluation phase also involves setting metrics. Once we understand where the problem is, we attach adequate metrics to the problem. This helps to characterize the magnitude of the challenge and later understand whether the problem has been solved or not or if other risks have materialized.

As a result of the third stage, the bottlenecks and opportunities of the current business processes have been identified, the processes to be changed have been selected, and knowledge of the necessary changes has emerged. Initial performance metrics are also set.

4. Creating a new business process or modifying an existing one

The fourth stage is creating or redesigning a new (to-be) process.

„When designing the process, we establish a vision of what this so-called ideal scenario will be like and a strategy for how we intend to solve the set goals," explains Mihkel Lauk.

When designing the to-be process, it is necessary to come up with the considerations needed for making the final decision. For example, how many new risks to take, how many resources to use and how it relates to the projected benefits. Creating a vision of the future can also end with the opposite realization that the planned investment and changes are not worth making.

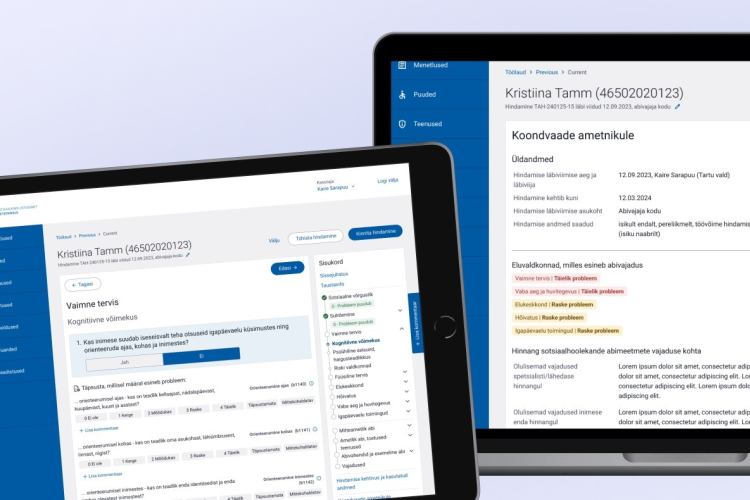

Service design, prototyping, and usability testing also occur in this phase. With service design, it is possible to maximize results - if you don't know the customer and don't know how to design customer-centred value, then things will not succeed. As a result of the fourth stage, we have created new business processes that are validated with end customers.

„Business analysis ends in the fourth stage with the creation of a new process. The next stages - management and implementation of changes- are the implementations of the analysis project results," explains Mihkel Lauk.

5. Change management and implementation

The fifth stage is the implementation of changes, i.e. creating a strategy to implement what has been planned. Often this stage is the most difficult. A new or changed business process can change someone's daily life: new competence needs are added, and people must work in a new way or acquire new skills. As a result of the fifth stage, new business processes start to work in the organization.

6. Analysis and control

The last step is to measure and control the change. The metrics set in the third step can be applied to the analysis. Planning a change is only possible if we can measure its success - it is necessary to know whether the change took place and whether the desired success occurred.

We must also check the side processes because risks may manifest elsewhere or in a different form than expected. As a result of the last stage, it becomes clear whether the change worked, to what extent it was successful, and whether the risks caused by the change have secretly manifested themselves in other business processes.

What is the value anyway?

Defining value has always been tricky because it can be difficult to define. If value cannot be identified or articulated, then the entire value creation assessment process may fail. Well-prepared organizations usually explain their brand's value proposition in a brand strategy.

„Generally speaking, value is what customers end up paying for. And the answer is not just the name of the product or service, but rather the feeling or emotion they get at the end of a successful transaction," reveals Mihkel Lauk.

During the business analysis project, we also define the business value. Some values may not be necessary for the end customer but are vital for the operation of the business. The business value needs to be compliant with the law.

For example, the activity must comply with the Personal Data Protection Act. Business value can also be risk mitigation. For example, you check a new customer's financial background and ability to pay before accepting an order.

How to measure value creation?

„When evaluating value creation, we find out which process activities are valuable in the business context and which are not," says Mihkel Lauk.

Value can be assessed both quantitatively and qualitatively. The quantitative evaluation method analyzes voluminous data, such as website visits, purchase statistics, financial data, delivery speed, market demand, etc.

Qualitative assessment of value creation is an art in itself - a business analyst provides an expert assessment that is designed precisely based on the project's goal and the selected business analysis methodologies.

Process activities can be evaluated from the point of view of both end-customer value and business value. The goal is to understand which steps within the process do not create value. For this, we can ask simple questions about each process.

Can this step be taken out? How much value does this movement create? Does the value change in the end client point of view when the activity is removed? Does the end customer even feel the difference? If the step cannot be taken out, then it is clear that the action creates value.

What is waste and how can waste be identified?

„Waste has different subcategories. "Waste is not necessarily related only to activities, but also to events and connections within the processes," explains Mihkel Lauk.

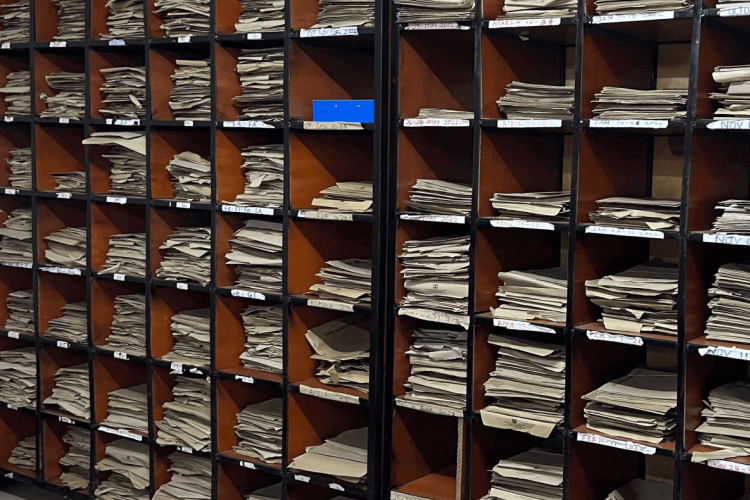

The first example is the waste that occurs through transfer. Information is usually transferred. Therefore, it is worth analyzing what information is transmitted and how. For example, sending a document on paper means a trivial expenditure of time and money.

At the same time, moving an electronic document can also be wasteful if someone has to manually retype the PDF data in the information system; the solution that eliminates waste is a machine-readable document instead.

Another waste is waiting. We should treat business process waiting times similarly to inventory that sits in a warehouse until it is cashed.

„The standstill of the business process or the status "work in progress" is a red flag- time is spent, but no value is created, or the value has not yet been delivered," states Mihkel Lauk.

Waiting can also arise from the participants' roles and responsibilities in the processes. When analyzing the roles, it is worth considering whether the right people have the right responsibilities - only in this case will they have the ability to control the process and create value as quickly as possible.

„In one case, the solution was to change the contract with the external partner so that the latter would have an enforced responsibility for meeting the deadline. Contractual sanctions made the partner act faster, time wastage decreased, the process became faster, and value was created sooner," recalled Mihkel Lauk.

We can reduce waiting time by discovering that the activities of a business process do not have to be linear but can also be parallel - thus saving time and creating value faster.

„Municipality digitalized the approvals of detailed plans, so that approvals could be given in parallel. Thanks to this change, we can say that time savings can be measured in years," Mihkel Lauk demonstrated.

The third category is the waste that results from rework. Such wastes can, in turn, be divided into three.

First, error-related waste caused by a process failure. The consequence is the repetition, re-making or re-doing of actions. This leads to wasted resources, delayed delivery, lost revenue and reputation damage. The solution is to identify errors and nip them in the bud.

Another subcategory is waste due to overwork, which results from processes that have competence gaps or involve perfectionists who over-finish all the details. When people are uncertain, they may seek reassurance and coordination through time-consuming meetings. The solution is to refer to the necessary training, review the meeting rules and give specific decision-making rights.

The third is waste due to overproduction, which consists of activities that do not contribute to the final value. For example, if a customer cancels an order halfway through, it should be analyzed whether it could have been foreseen and what is the reason for the cancellation.

In the second scenario, the result of the process is delivered to the customer, but the customer no longer needs it. In this case, it is worth investigating why the deliverable no longer offers value to the customer. If delivery is time critical, can we deliver value at the right time?

In conclusion

Even small changes help create value and reduce waste. However, the challenge is to find areas for improvement and redesign business processes. Therefore, if you want to map your business's bottlenecks and opportunities but have no experience, we recommend involving a business analyst in the project.